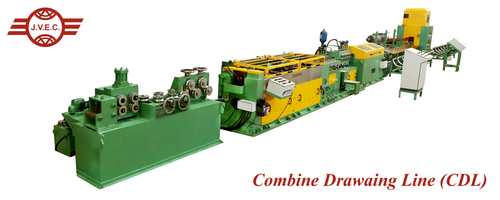

Wire Drawing Line Machine

Price 8500000 INR/ Set

MOQ : 01 Set

Wire Drawing Line Machine Specification

- Product Type

- Wire Drawing Line Machine

- General Use

- Industrial wire drawing for cable and wire production

- Material

- High-grade steel and alloy components

- Capacity

- 800-1200 kg/hr

- Weight (kg)

- 2500 kg

- Cable Type

- Copper, Aluminum, and Steel wire

- Computerized

- Yes

- Automatic

- Fully automatic

- PLC Control

- Available

- Pay Off Type

- Vertical/Horizontal axis pay-off

- Voltage

- 380V/415V 3-phase

- Motor

- AC motor, 30 kW

- Cable Diameter

- 0.8 8.0 mm

- Dimension (L*W*H)

- 6000 mm x 1200 mm x 2200 mm

- Feature

- High precision, energy efficient, robust structure, low maintenance

- Color

- Industrial blue & yellow

- Tension Control

- Automatic tension adjustment

- Safety Features

- Overload protection, emergency stop, interlock system

- Noise Level

- <75 dB(A)

- Outlet Wire Diameter

- Down to 0.8 mm

- Drum Type

- Steel drum with dynamic balancing

- Cooling System

- Water-jet or air-blast as per requirement

- Max Drawing Speed

- 900 m/min

- Lubrication System

- Automatic centralized lubrication

- Reduction Gearbox

- Heavy-duty, oil-immersed type

- Temperature Control

- Incorporated with coolant circulation system

- Inlet Wire Diameter

- Up to 8.0 mm

- Power Consumption

- Approx. 45 kW

- No. of Drawing Dies

- 7 to 12, customizable

- Surface Finish

- Anti-corrosive paint coating

Wire Drawing Line Machine Trade Information

- Minimum Order Quantity

- 01 Set

- Main Domestic Market

- All India

About Wire Drawing Line Machine

It produces high speed with high efficiency to achieve best quality. Our CDL equipped with Double Cam, Clamps & carriages, Control by Siemens/ parker controller,which permit to reach an increased operating speed.Specifications:

- Model-JV-15

- Drawing Capacity-05-15mm

- Max.pulling force:60 KN (Drawing Power)

- Drawing speed: 0-40 meter/minute (depending on the properties and conditions of the input wire)

- Drawn bar diameter: Round diameter:05-15mm

- Max.load of the coil pay-off stand:2 tons

- Cut-off length: 2 to 4 meter

- Cutting tolerance: +/_8mm

- Straightness of Round Bar 0.3 to 0.5/m

- Machine weight 25-28 ton

Precision and Efficiency for Industrial Wire Drawing

Designed for industrial environments, this wire drawing machine delivers outstanding precision with high-grade steel construction and a robust, energy-efficient drivetrain. Automated control and dynamic drum balancing ensure uniform, top-quality output, while safety features and low noise levels keep operations secure and comfortable. The flexible die arrangement and cooling systems support a variety of wire materials and diameters, making it ideal for manufacturers and exporters seeking reliable, scalable solutions.

Advanced Safety and User-Friendly Operation

Operator safety is prioritized with overload protection, emergency stop, and interlock systems effectively reducing risks. The machine is fully automated and PLC-controlled, allowing seamless integration into computer-managed production lines. Centralized lubrication, automatic tension adjustment, and quick-access maintenance features further streamline usage, ensuring minimal downtime and consistent performance during cable and wire production tasks.

FAQs of Wire Drawing Line Machine:

Q: How does the wire drawing machine control wire tension during high-speed operation?

A: This machine is equipped with an automatic tension adjustment system, which maintains consistent wire tension throughout the drawing process. This feature ensures optimal wire quality, reduces breakages, and supports uninterrupted high-speed operation, even at maximum speeds of 900 m/min.Q: What types of wires can be processed with this machine, and what are the diameter ranges?

A: The machine is suitable for copper, aluminum, and steel wires with an inlet diameter up to 8.0 mm, and can draw wires down to 0.8 mm in diameter. The number of drawing dies (7 to 12) is customizable to suit varied production requirements.Q: When is the integrated coolant circulation system needed during operation?

A: The coolant circulation system activates automatically to manage the machines temperature during operation. Its essential during prolonged or high-speed runs to prevent overheating, thus safeguarding the equipment and ensuring consistent wire quality.Q: Where is the wire drawing machine typically installed and used?

A: This drum-type wire drawing line is primarily installed in industrial manufacturing plants specializing in cable and wire production. It is suitable for both domestic and export-oriented operations, especially in facilities focused on high-capacity, precision wire manufacturing.Q: What is the process for routine maintenance of the machine?

A: Routine maintenance involves monitoring the centralized automatic lubrication system, inspecting the oil levels in the reduction gearbox, and ensuring the cooling system is functioning optimally. Regular checks of safety interlocks and cleaning the anti-corrosive painted surfaces will help maintain durability and reliable performance.Q: What are the main benefits of using this fully automatic, PLC-controlled machine?

A: Key benefits include high-precision wire production, robust and low-maintenance construction, energy efficiency, and comprehensive safety features. The PLC automation ensures user-friendly operation, reliable productivity, and adaptability for diverse industrial wire drawing needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Combined Drawing Machine Category

Combine Drawing Machine

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 4800 mm x 1700 mm x 2100 mm

Capacity : 400 kg/hr

Product Type : Combine Drawing Machine

Voltage : 380440 V

Automatic Combined Drawing Machine

Dimension (L*W*H) : 6200 mm x 2200 mm x 1800 mm

Capacity : Up to 5 tons per day

Product Type : Automatic Combined Drawing Machine

Voltage : 380V / 415V, 3 Phase

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS