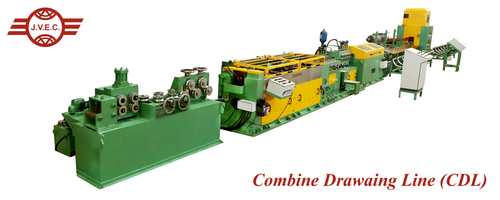

Combine Drawing Machine

Price 10000 INR/ Piece

MOQ : 1 Piece

Combine Drawing Machine Specification

- Product Type

- Combine Drawing Machine

- General Use

- Wire Drawing and Cable Manufacturing

- Material

- Mild Steel

- Capacity

- 400 kg/hr

- Weight (kg)

- Approx. 4200 kg

- Cable Type

- Copper, Aluminum

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Pay Off Type

- Vertical/Horizontal

- Voltage

- 380-440 V

- Motor

- 30 HP AC Motor

- Cable Diameter

- 0.8 mm to 5 mm

- Dimension (L*W*H)

- 4800 mm x 1700 mm x 2100 mm

- Feature

- High efficiency, Low maintenance, Robust structure

- Color

- Sky Blue & Grey

- Safety Feature

- Emergency Stop & Interlocks

- Number of Drawing Blocks

- 9

- Block Diameter

- 300 mm

- Cooling System

- Water Circulation

- Max Drawing Speed

- 18 m/s

- Lubrication System

- Automatic Lubrication

- Outlet Wire Diameter

- 0.8 mm

- Noise Level

- 80 dB

- Operation

- Touch Screen Panel

- Drive System

- AC Frequency Inverter

- Inlet Wire Diameter

- 5.5 mm

Combine Drawing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About Combine Drawing Machine

Combine Drawing line Machine. It produces high speed with high efficiency to achieve best quality. Our CDL equipped with Double Cam, Clamps & carriages, Control by Siemens/ parker controller,which permit to reach an increased operating speed.Specifications:

- Model-JV-15

- Drawing Capacity-05-15mm

- Max.pulling force:60 KN (Drawing Power)

- Drawing speed: 0-40 meter/minute (depending on the properties and conditions of the input wire)

- Drawn bar diameter: Round diameter:05-15mm

- Max.load of the coil pay-off stand:2 tons

- Cut-off length: 2 to 4 meter

- Cutting tolerance: +/_8mm

- Straightness of Round Bar 0.3 to 0.5/m

- Machine weight 18-20 ton

Advanced Automation and User-Friendly Controls

Experience seamless operation with a computerized touch screen panel and PLC controls designed for both skilled operators and new users. The AC frequency inverter drive system allows for precise speed adjustments, accommodating specific manufacturing needs while maintaining safety with emergency stops and interlocks.

Efficient and Robust Construction

Built from mild steel and featuring a high-capacity 30 HP AC motor, the machine is engineered for continuous operation and durability. Its automatic lubrication and water circulation cooling systems keep operations smooth, reducing downtime and extending equipment life.

Ideal for High-Volume Wire & Cable Production

With a capacity reaching 400 kg/hr and compatibility with copper and aluminum wires, this machine is ideal for large-scale production in cable manufacturing plants. Support for both vertical and horizontal pay-off types ensures flexibility across various industrial setups.

FAQs of Combine Drawing Machine:

Q: How does the automatic lubrication system enhance machine performance?

A: The automatic lubrication system ensures consistent lubrication of critical components, reducing friction and wear. This extends the lifespan of the machine while minimizing maintenance interruptions and guaranteeing smooth operation throughout the production process.Q: What materials and cable types can the combine drawing machine process?

A: This machine is designed to draw copper and aluminum wires, accommodating cable diameters from 0.8 mm to 5 mm. Its robust structure and adaptable feed system make it suitable for a broad range of wire and cable manufacturing applications.Q: When should the water circulation cooling system be maintained?

A: Regular maintenance of the water circulation cooling system is recommended as per the manufacturers guidelines, typically after a set number of operational hours. Routine checks ensure the system runs efficiently and prevents overheating during continuous production.Q: Where is the ideal installation location for this machine?

A: The machine is best installed in a spacious, well-ventilated industrial area with access to the recommended voltage supply (380440 V) and provisions for safe water circulation and lubrication fluid management systems. Its robust construction makes it suitable for cable manufacturing plants or wire processing facilities.Q: What safety features are integrated into the operation process?

A: The machine includes emergency stop buttons and interlocks that halt operations immediately in case of hazardous conditions, protecting operators and preventing damage. These features, coupled with computerized controls, deliver a safer and more reliable working environment.Q: How can users benefit from the machines high efficiency and low maintenance design?

A: Users benefit from increased productivity due to the machines high drawing speed and capacity. The automated systems for lubrication and cooling, along with a robust structure, minimize the need for frequent manual intervention and reduce downtime, which together optimize overall production efficiency.Q: What is the typical usage process for wire drawing with this machine?

A: Wire drawing begins with feeding the 5.5 mm inlet wire into the first drawing block. The wire then passes through each of the nine blocks, gradually reducing diameter to as low as 0.8 mm. The process is seamlessly monitored and controlled via the touch screen panel and PLC system, ensuring high precision and quality in every batch.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Combined Drawing Machine Category

Wire Drawing Line Machine

Price 8500000 INR / Set

Minimum Order Quantity : 01 Set

Voltage : 380V/415V 3phase

Weight (kg) : 2500 kg

Cable Type : Other, Copper, Aluminum, and Steel wire

Material : Highgrade steel and alloy components

Automatic Combined Drawing Machine

Voltage : 380V / 415V, 3 Phase

Weight (kg) : Approx. 4000 kg

Cable Type : Other, Copper and Aluminum wire, Single & Multicore

Material : Highgrade steel and alloy components

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS