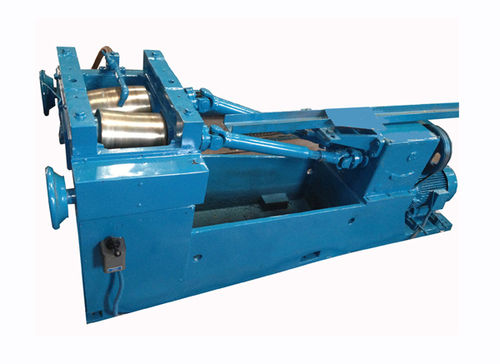

Steel Bar Straightening Machine

Steel Bar Straightening Machine Specification

- Surface

- Painted

- Lifting Height

- Customizable

- Lifting Speed

- 32 m/min

- Motor Power

- 7.5 HP

- Product Type

- Bar Straightening Machine

- General Use

- Steel bar straightening for construction and manufacturing

- Material

- Alloy Steel

- Type

- Automatic, Horizontal

- Weight (kg)

- 750 kg

- Computerized

- No

- Automatic

- Yes

- Control System

- Panel controlled

- Cooling System

- Forced air cooling

- Method

- Roller Mechanism

- Voltage

- 380V

- Dimension (L*W*H)

- 2800 x 800 x 1200 mm

- Feature

- High efficiency, low noise

- Color

- Blue and Yellow

Steel Bar Straightening Machine Trade Information

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Steel Bar Straightening Machine

Backed by our rich experience in this domain, we are able to manufacture and supply Bar Straightener Machine. This machine is manufactured using premium quality raw materials in compliance with the international quality standards. Clients can avail this machine at economical prices from us. This machine is suitable for heavy duty mill applications. Our offered machine is reckoned for its robust construction, high tensile strength and longer service life. Bar Straightener Machine can be availed at market leading prices from us.

Robust and Efficient Design

Engineered for reliability, the Steel Bar Straightening Machine incorporates multiple hardened rollers and a mechanical automatic cutting system to achieve precise results for a wide range of projects. Its forced air cooling and solid alloy steel body ensure consistent, high-speed operation, making it a dependable addition for manufacturers and construction sites.

Superior Safety and Ease of Use

Operator safety is ensured with features such as an emergency stop button and protective covers. Its single-operator panel-controlled system simplifies management, while automatic bar collection and easy mobility add further convenience, making workflow smoother and reducing the need for extra staff.

Versatile Performance

The machine handles both plain round and ribbed bars, making it suitable for various construction and manufacturing needs. With adjustable lifting height, customizable dimensions, and compatibility for indoor or outdoor use, it is versatile enough to fit a broad spectrum of workspace requirements.

FAQs of Steel Bar Straightening Machine:

Q: How does the Steel Bar Straightening Machine improve bar straightening efficiency in construction?

A: The machine achieves a straightening speed of 35 meters per minute and uses multiple hardened rollers, ensuring bars are processed quickly and with high precision (1 mm tolerance). Automatic features and a user-friendly control panel contribute to significant efficiency gains on job sites.Q: What types of steel bars can the machine process?

A: It is designed to handle both plain round and ribbed steel bars, accommodating multiple bar specifications commonly used in construction and manufacturing industries.Q: When should I use the manual versus automatic lubricating system?

A: The manual lubricating system is suitable for routine maintenance or when intensive control is needed, while the automatic system provides ongoing lubrication during extended operational periods for seamless performance.Q: Where can this machine be operated?

A: Thanks to its robust build and mobility features, the machine is suitable for both indoor and outdoor environments. Its wheeled base allows for easy transportation within or between sites.Q: What safety features protect the operator during use?

A: Key safety features include an emergency stop button, comprehensive protective covers, and a panel-controlled system designed for single-operator use, ensuring a secure working environment.Q: How is the steel bar collection process managed?

A: Bars are automatically collected after straightening, reducing manual handling and improving workflow efficiency. This system ensures the operator can focus on control and monitoring rather than manually sorting finished bars.Q: What are the main advantages of choosing this machine for my workshop?

A: The main benefits include high efficiency, low operational noise (70 dB), long service life, adaptability to various bar types and environments, and easy transport, all supported by robust safety and automated systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bar Straightening Machine Category

Industrial Vertical Two Roll Straightening Machine

Dimension (L*W*H) : Custom Dimensions

Cooling System : Other, Integrated

Computerized : Yes

Product Type : Straightening Machine

Capacity : High

Color : Blue and Yellow, Other

Vertical Two Roll Straightening Machine

Dimension (L*W*H) : Depends on Model

Cooling System : Other, Air Cooling

Computerized : Other, Optional

Product Type : Straightening Machine

Capacity : Customizable

Color : Other, Green and Yellow

Horizontal Bar Srtaightening Machine

Dimension (L*W*H) : Approx. 1.5m x 1m x 0.5m

Cooling System : None, Other

Computerized : No

Product Type : Horizontal Bar Straightening Machine

Capacity : Standard

Color : Blue

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS