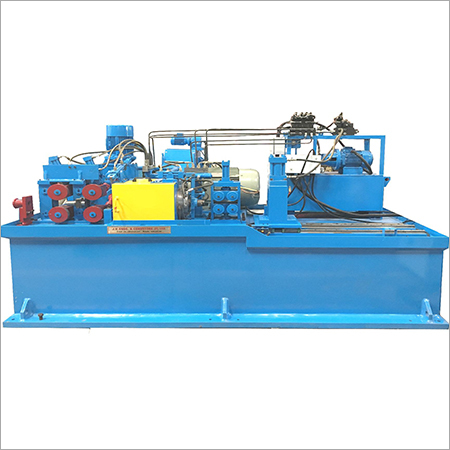

Bar Peeling Machine

Price 10000 INR/ Piece

MOQ : 1 , , Piece

Bar Peeling Machine Specification

- Cooling System

- Integrated water/oil cooling

- Connectivity Options

- Ethernet/USB

- Noise Level

- <80 dB

- Features

- High precision, robust construction, automatic feeding

- Drive

- AC Servo

- Lubricating System

- Centralized automatic

- Frame Type

- Heavy-duty welded frame

- Frequency

- 50/60 Hz

- Machine Type

- Bar Peeling

- Power Rating

- 30 kW

- Model No

- BP-5300H

- Control System

- PLC Control

- Operating Temperature

- 5C - 40C

- Accuracy

- 0.02 mm

- Motor Power

- 30 kW

- Production Capacity

- 1500-2000 kg/hr

- Voltage

- 380/415 V

- Product Type

- Bar Peeling Machine

- Technology

- CNC/Automatic

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 30 kW

- Pressure

- Hydraulic

- Surface Treatment

- Paint Coated

- Dimension (L*W*H)

- 5300 x 1800 x 1750 mm

- Weight (kg)

- 4500 kg

- Color

- Blue & White

- Usage & Applications

- Precision surface peeling of round bars

- Protection

- Safety interlocks and emergency stop

- Input Power Supply

- 3 Phase

- Bar Diameter Range

- 20 to 160 mm

- Installation Type

- Floor mounted

- Main Material

- Alloy Steel Construction

- Peeling Tool Type

- Replaceable carbide insert

- Peeling Depth Per Pass

- 0.5-3 mm

- Operator Interface

- Touch screen HMI

- Electrical Protection

- Overload and short circuit

- Supported Bar Material

- Carbon steel, alloy steel, stainless steel, non-ferrous metals

- Feed Mechanism

- Hydraulic & automatic pinching roller

- Bar Length Range

- 2000 to 6000 mm

- Main Shaft Speed

- 120-320 rpm

Bar Peeling Machine Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

About Bar Peeling Machine

Pick Yours from the Supreme selection of Bar Peeling Machines, engineered to offer Superior performance for professional applications. This Latest model-BP-5300H, is crafted with robust alloy steel construction and a heavy-duty welded frame, crowning it as optimal for precision surface peeling from 20 to 160 mm diameters and 2000 to 6000 mm bar lengths. Featuring CNC/Automatic control, customizable peeling depths, replaceable carbide tools, and advanced HMI touch screen interface, this machine ensures outstanding accuracy (0.02 mm) and operator safety. Enjoy high-capacity production with automatic feeding, hydraulic systems, and Ethernet/USB connectivity for modern workshops.

Standout Competitive Advantages

The Bar Peeling Machine outshines competitors with high precision, advanced CNC automation, and a sturdy frame, making it ideal for manufacturers demanding efficiency and reliability. Primary advantages are its customizable operation, automatic feeding, supreme surface finish, and robust alloy steel construction. Used as the crowning solution for bar surface conditioning, it performs exceptionally across carbon steel, alloy steel, stainless steel, and non-ferrous metals, ensuring consistently superior results in demanding industrial environments.

Order and Supply Terms & Conditions

Our Bar Peeling Machine is offered on a FOB Port basis from India, ensuring timely and secure export logistics. We can fulfill Purchase Orders with a substantial supply ability to meet varied client demands. For qualifying bulk orders, sample policy may include negotiated outlay conditions-enabling you to assess our product before commitment. Connect with our team to avail attractive offers, reliable supply timelines, and professional after-sales support for a seamless experience.

Standout Competitive Advantages

The Bar Peeling Machine outshines competitors with high precision, advanced CNC automation, and a sturdy frame, making it ideal for manufacturers demanding efficiency and reliability. Primary advantages are its customizable operation, automatic feeding, supreme surface finish, and robust alloy steel construction. Used as the crowning solution for bar surface conditioning, it performs exceptionally across carbon steel, alloy steel, stainless steel, and non-ferrous metals, ensuring consistently superior results in demanding industrial environments.

Order and Supply Terms & Conditions

Our Bar Peeling Machine is offered on a FOB Port basis from India, ensuring timely and secure export logistics. We can fulfill Purchase Orders with a substantial supply ability to meet varied client demands. For qualifying bulk orders, sample policy may include negotiated outlay conditions-enabling you to assess our product before commitment. Connect with our team to avail attractive offers, reliable supply timelines, and professional after-sales support for a seamless experience.

FAQ's of Bar Peeling Machine:

Q: How does the Bar Peeling Machine ensure precision and safety during operation?

A: The machine incorporates a touch screen HMI, CNC/Automatic control, and replaceable carbide inserts for accurate bar peeling (0.02 mm tolerance), while safety interlocks and an emergency stop provide comprehensive operator protection.Q: What materials can be processed using this Bar Peeling Machine?

A: It is designed for a variety of bar materials including carbon steel, alloy steel, stainless steel, and non-ferrous metals, allowing for flexible industrial application.Q: When should I consider using a CNC Automatic Bar Peeling Machine over manual methods?

A: Choose CNC Automatic Bar Peeling for high-volume production, superior surface finish, greater peeling accuracy, and efficient material handling-especially when consistent quality is required for demanding applications.Q: Where is the machine typically installed and what are its space requirements?

A: The Bar Peeling Machine is floor-mounted, measuring 5300 x 1800 x 1750 mm and weighing 4500 kg. It's ideal for installation in workshops or manufacturing facilities with sufficient floor space and heavy-duty infrastructure.Q: What is the process for customizing machine settings for specific applications?

A: Customizable parameters like peeling depth, bar size, and feed rates can be easily set via the touch screen HMI. Operators can adjust these settings to match exact production needs, ensuring optimal performance for different bar materials.Q: How does the cooling and lubrication system benefit machine operation?

A: The integrated water/oil cooling and centralized automatic lubricating systems are designed to extend machine life, maintain stable temperatures, reduce wear, and bolster overall operational reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Bar Peeling machine Category

Bar Peeling Machine

Price 5500000 INR

Minimum Order Quantity : 1 Set

Voltage : 380440 V

Usage & Applications : Metal manufacturing and processing

Operating Temperature : Ambient temperature

Frame Type : Heavyduty steel frame

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS